Solutions

Waffles, Toaster Pastries and Donuts

Accurate size, shape and color information for randomly oriented, fast moving products.

Vision Inspection of Waffles, Toaster Pastries and Donuts

Bench-top, over-line, and in-line 3D and color imaging systems from Montrose are ideal for virtually any discrete food product that require size, shape, and color measurements. Products of any size and shape may be measured, the data displayed, and report generated. Montrose has produced systems for a wide range of food applications, such as colorful toaster pastries, sorting of pani puri, identification of components in sealed single serve meal containers, and full trays of candy.

Machine vision systems have the advantage of:

- Produce quantitative data that allows producers to create and alter processes to increase efficiency

- Reduce human error that results from qualitative inspection along with variance between observers

- Increase safety and hygiene through non-contact measurement

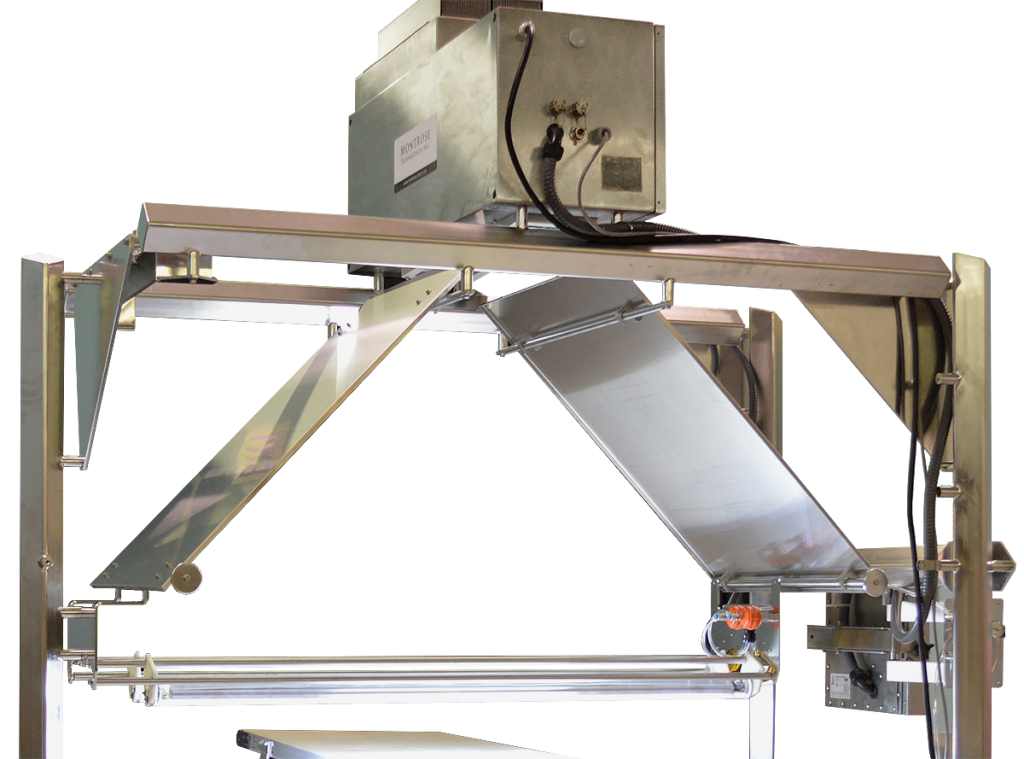

Our products are well established in the food industry, including a wide range of innovations such as bottom color scanning, individual piece rejection, automatic laning/balancing for packaging, box loading, and tray handling. Every system is developed in conjunction with our customers to ensure that the installed solution meets all of the customer’s project requirements.

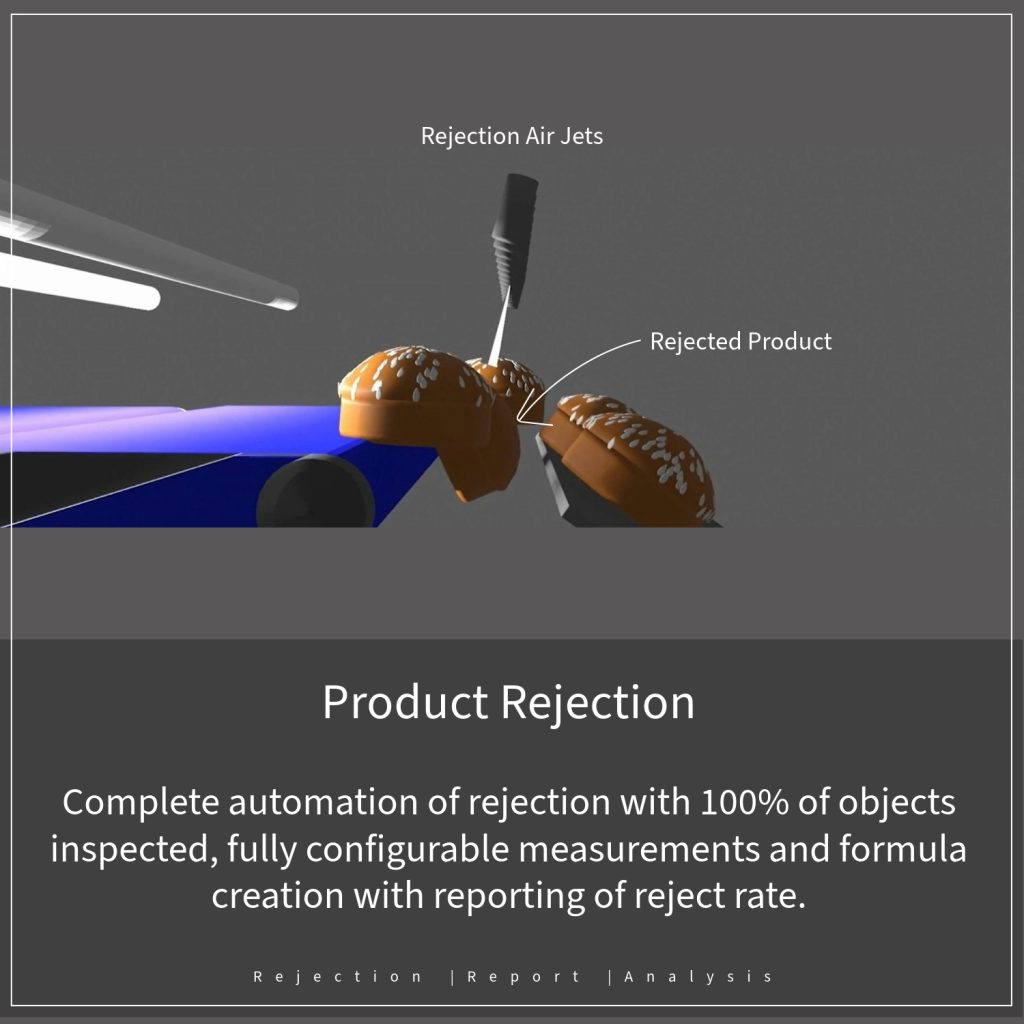

Each rejection mechanism is application specific and can be adapted to virtually any food.

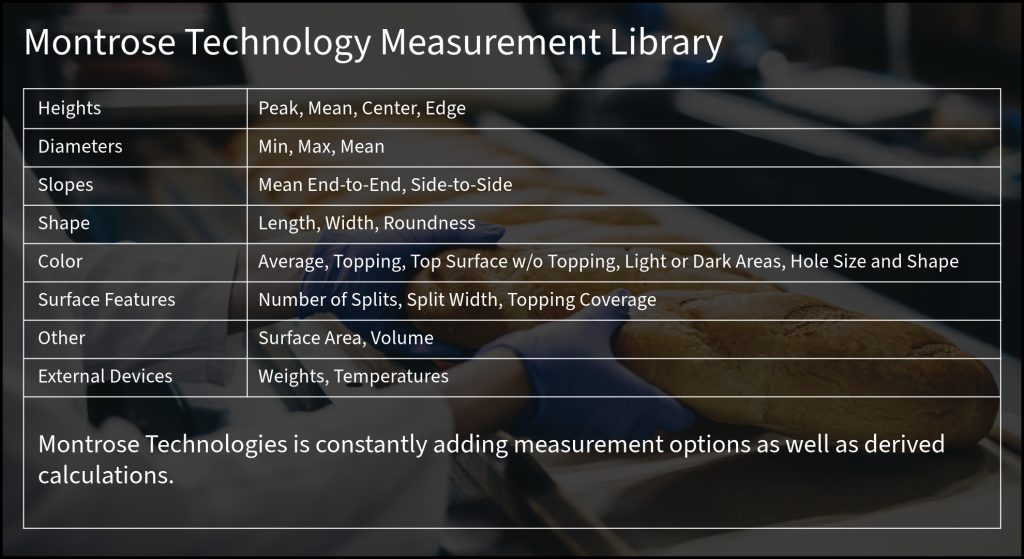

Inspection System Measurement Capability

Whether you want to sample or provide 100% inspection, Montrose Technologies has a solution to match your application.

Benchtop

The complete, stand-alone SnapQC™ system uses a high-speed, non-contact imaging method to capture a wide range of object information such as color, height, diameter, slope, symmetry, length, volume and weight.

In-line

The MT-Series™ of in-line systems allow 100% inspection with top and bottom color and a full set of rejection options. The systems are easy to use, sanitize and have a low annual maintenance cost and provide real-time data for operators.

Over-line

FocalPoint™ over-line systems can be incorporated into an existing production line. They are easily installed, versatile, low-cost turn-key solutions for continuous inspection which provide real-time data for operators.

Types of Analysis and Rejection

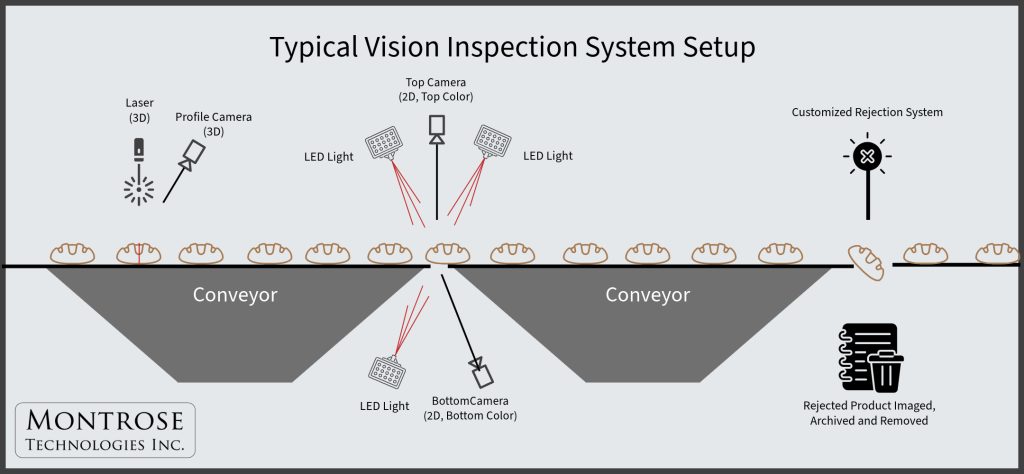

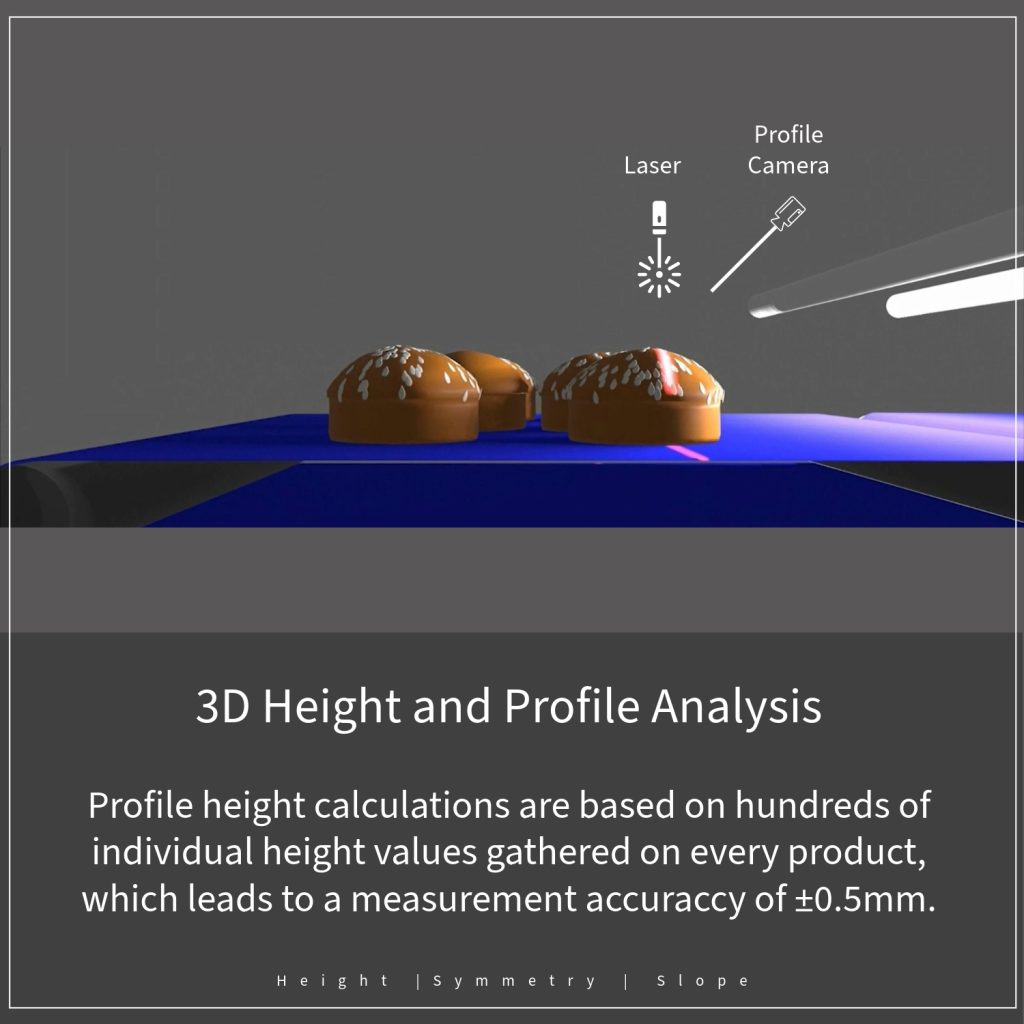

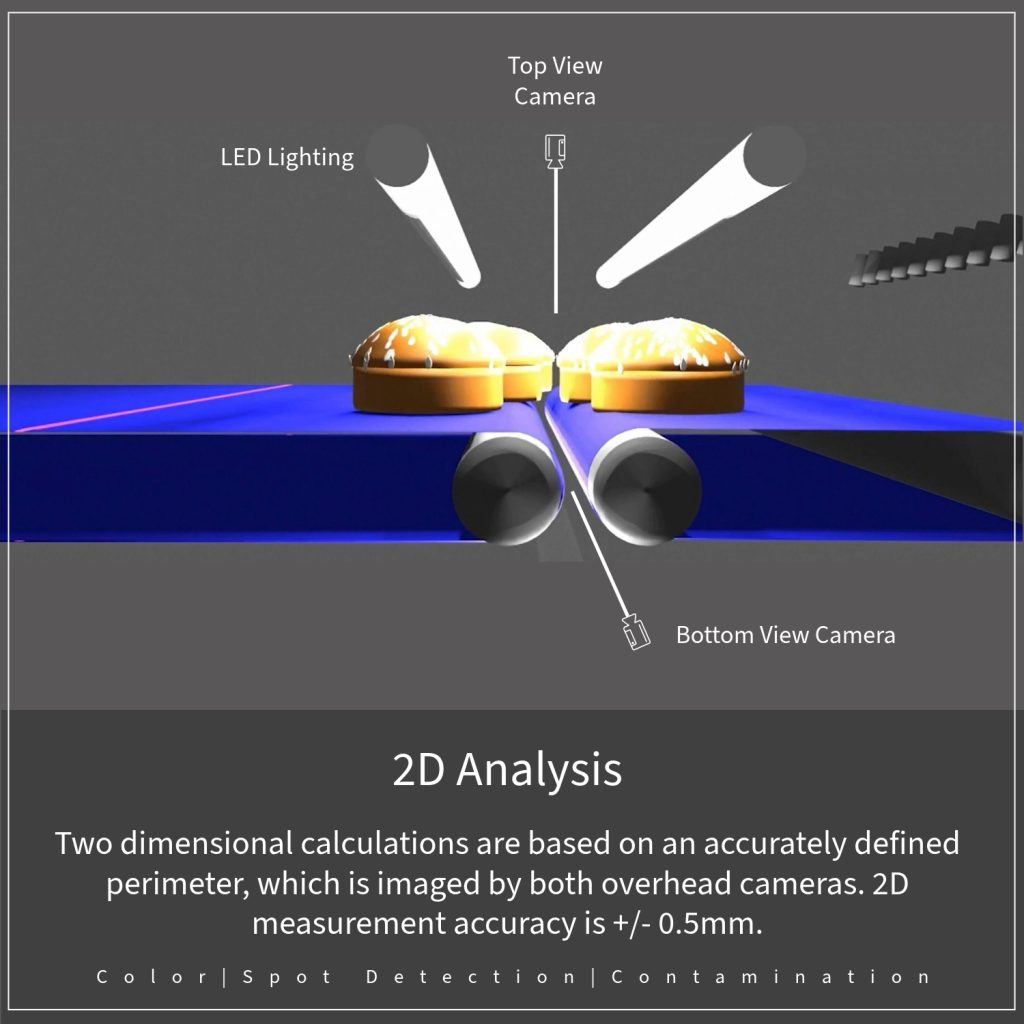

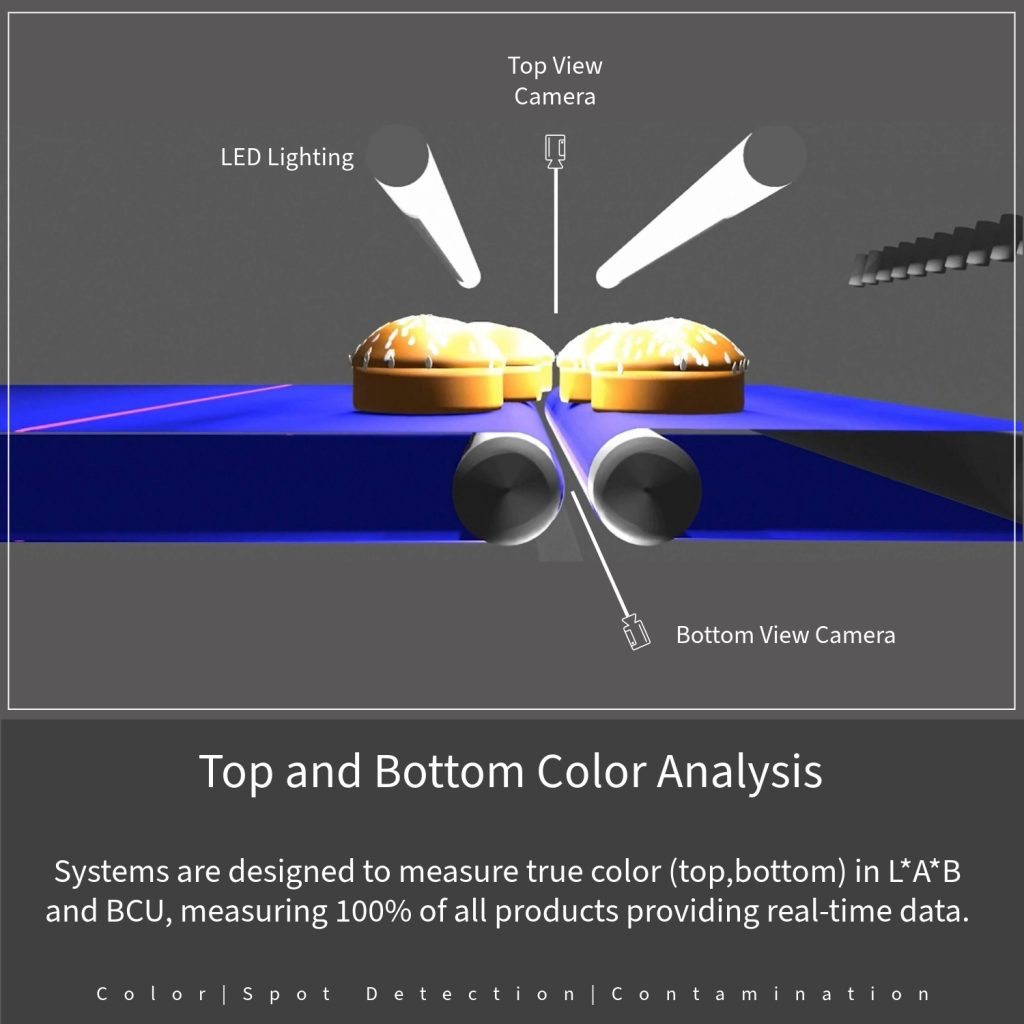

Vision inspection systems employ high-speed cameras and lasers in combination with Montrose imaging software to detect and measure randomly oriented and sized objects on a conveyor belt. Data from the laser and imaging devices produce 2D, 3D and color information which is fed into the analysis software. LED lighting systems are designs with the specific product the system is analyzing to ensure the most efficient imaging occurs. Each system, whether benchtop, in-line or over-line, is designed along the same principles. The laser and profile camera produce the three-dimensional information while the separate top and bottom camera perform the two dimensional and color analysis.

Rejection systems vary between systems and product types and are designed according to customer specification. Montrose develops and manufactures a complete set of solutions for the baked goods and snack food industry.

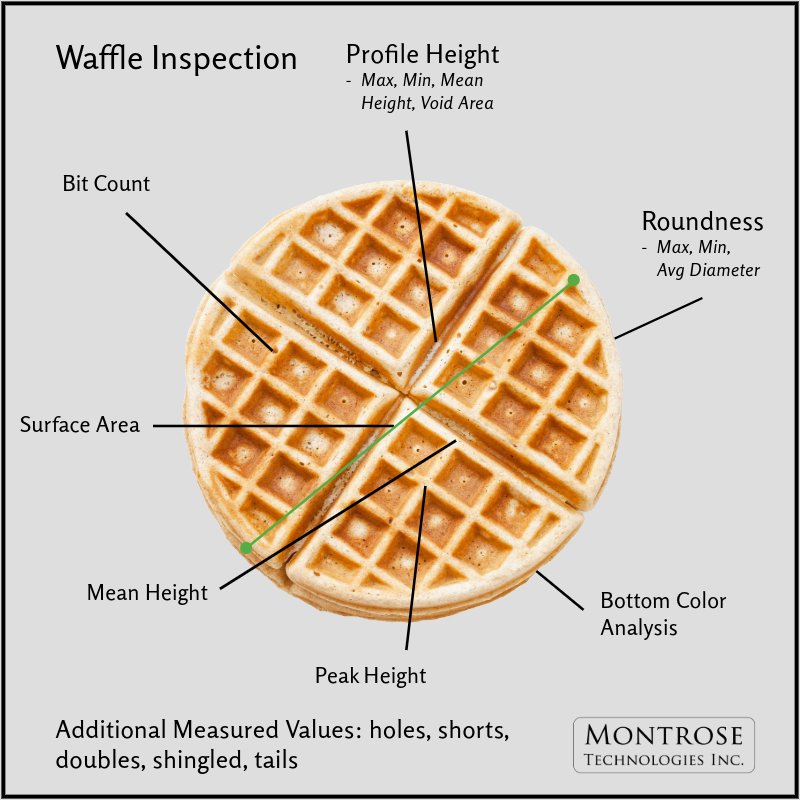

3D Measurements

- Profile height calculations

- Slope

- Mean height

- Peak height

- Center height

- Side-to-side slope

- End-to-end slope

2D Analysis of Shape

- Mean diameter

- Maximum diameter

- Minimum diameter

- Surface Area

- Volume

- Roundness

- Width/Length

Top and Bottom Color

- Top average color

- Bottom average color

- Area missing topping

- Topping % area covering

- Split width

- Light and dark area

- Hole size and shape

Rejection Features

- Reject rates by cause with fault type and alarm

- Rejected product displayed to operator and imaged

- Generate Pareto charts

- Rejection settings are configurable

Vision System Components

In-line and Over-line Inspection

The type and size of food product transported through the vision system will determine the number of cameras needed for the measurement requirements, the individual product rejection method, and hygienic/environmental considerations. Furthermore, vision inspection systems may include other customized material handling solutions such as automatic de-kissing of product, automatic box loading, and multi-route sorting.